It seems we can’t find what you’re looking for. Perhaps searching, or one of the links below, can help.

Recent Posts

- Communicating with the VESC using UART

- VESC – Writing Custom Applications

- VESC – Open Source ESC

- Connecting a programmer/debugger to my custom STM32 PCBs

- Open Source ESC Video Logging on Electric Longboard

- Chosing the right BLDC motor and battery setup for an electric skateboard

- Startup torque on sensorless BLDC motors

- Testing my custom motor controller

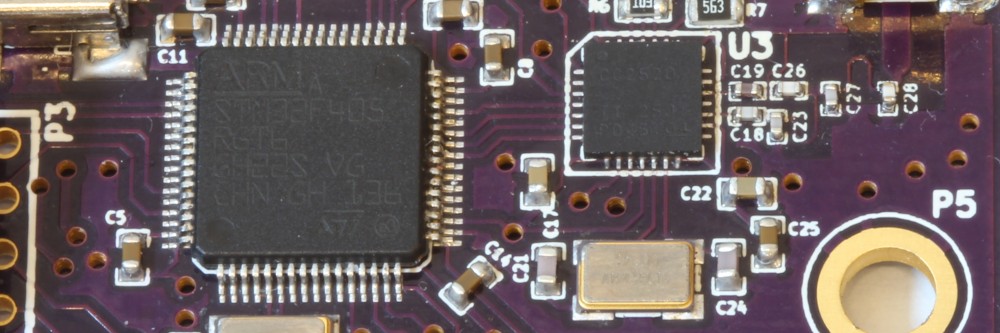

- ChibiOS on my cc2520+stm32f4 boards

- A custom BLDC motor controller (a custom ESC)

Most Used Categories

- Projects (19)

- Embedded Software (16)

- Electronics/Hardware (10)

- Software (3)

- Tutorials (8)

- News/Announcements (6)

Archives

Try looking in the monthly archives. 🙂

Tags

- ARM

- arm-gcc

- ARM ESC

- ARM toolchain

- BLDC

- CC2520

- Chalmers

- ChibiOS

- Contiki

- CRF

- custom ESC

- discovery

- DRV8301

- DRV8302

- Eclipse

- ESC

- float

- gdb

- hardfloat

- IEEE

- linux

- LPC1768

- LPC1769

- MP3

- open source

- Papers

- PCB

- p_oshw

- robot-sm

- RobotChallenge

- RobotSM

- sensors

- Sleipner

- SSH

- STLink

- stm32

- STM32F4

- STM32F4 Discovery

- toolchain

- Tunnel

- tutorial

- Ubuntu

- usb

- USB-CDC

- ws2811